JOSEPH LIM AUGUST 27, 2018

Introduction / Global Green’s Objective:

Collaborate with partners to create up to 3 different scenarios for local food waste processing and consumption. Partners on this project can include landscape architects, builders, cities, and developers. When possible, we’re seeking to conduct webinars, workshops, and/or pilot programs to demonstrate and evaluate solutions. The targeted audience is municipalities looking to expand their co-digestion efforts.

Co-digestion is a process in which energy-rich organic waste such as FOG (fat, oils, and grease) and food scraps are added to an anaerobic digestion system in a process to boost biogas production. This process can potentially help landfills by diverting food waste and FOG, lessening methane emissions and the overall waste received. Wastewater treatment facilities have the potential to capture the methane produced by food waste and use it as an energy source or inject gas back into the pipeline. This can lead to cost savings in energy expenses as on-site energy production increases, as well as increased revenue generated through tipping fees. Communities can use existing infrastructure to generate renewable energy (i.e. biogas) to become more sustainable, which in turn can also create jobs to collect, manage, and process the food waste.

This document provides examples of co-digestion projects completed by municipalities, pre-processing cost estimates, scenarios and different scales of co-digestion.

Technologies, Equipment, and Other Considerations

Evaluating Capacity

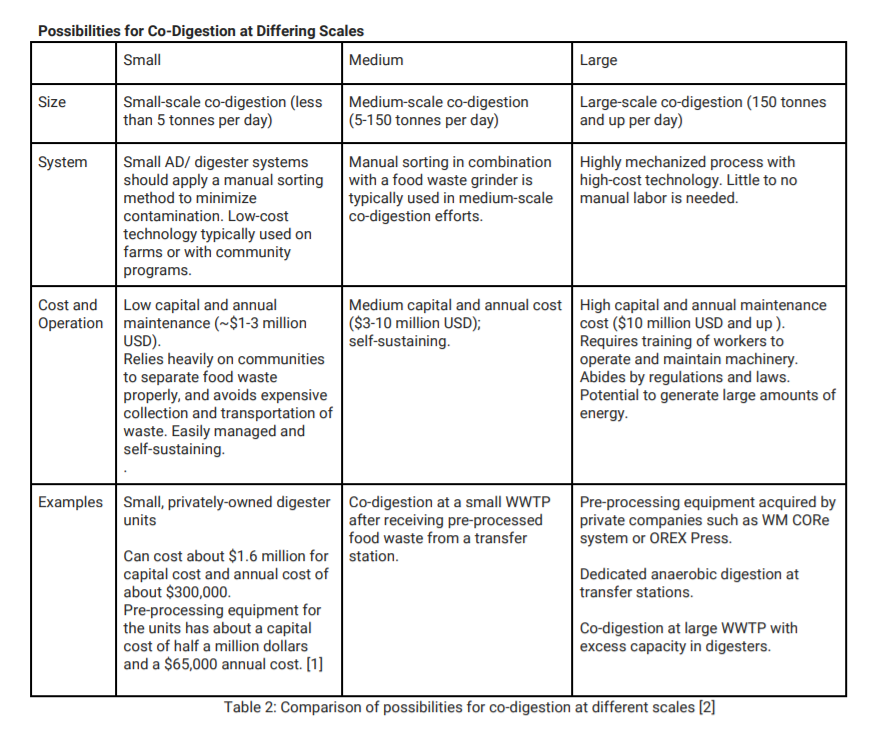

Cities seeking options for co-digestion at their local wastewater treatment plants should first evaluate digester capacities before accepting food waste at their WWTP. Also, cities or private companies would have to invest in infrastructure/technologies for co-digestion to work, whether in a wastewater treatment plant or at dedicated sites like a transfer station.

Scaling Co-Digestion

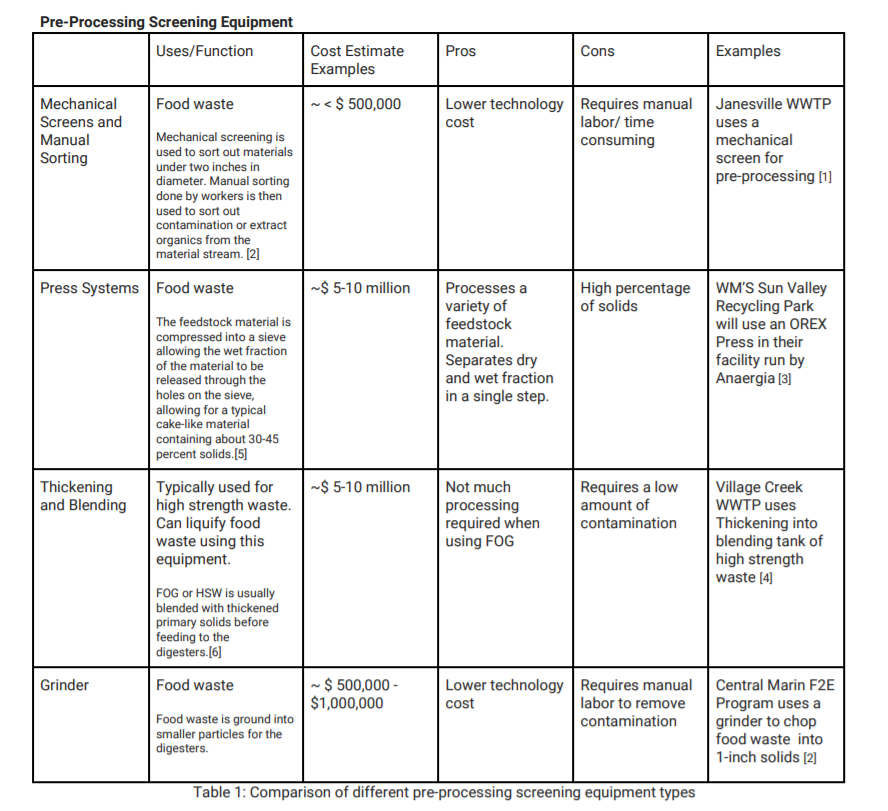

Pre-processing Stage:

Feed stock Material

Quantity, quality, and digestibility of the feedstock need to be considered, as well as the extent of contamination in the waste stream, and the variation and consistency of waste throughout the seasons.

Feed stock Sources

Feedstock is sought from residential, commercial, and/or industrial sources. Community outreach programs and policies should be considered to educate residents and businesses on how to properly sort food waste that is free of contamination. Policy considerations should include a distance threshold for compliance, affected facilities, and implementation.

NYC Case Study Example[0]:

Since 2016, New York City has implemented a food waste collection distance threshold consisting of a 100-mile radius of the City. Facilities affected by this threshold are as follows: hotels with 150+ rooms, arenas and stadiums with the seating capacity of 15,000+ people, food manufacturers with a floor area of 25,000+ square feet, food wholesalers with a floor area of 20,000+ square feet, and other generators may be added as processing capacity increases.

Scenarios

Scenario 1: Anaerobic digestion using contaminate-free organics (in a bucket) placed in digesters

Digesters would accept high-quality feed stock that is suitable for digestion and free of contamination. Whether digesters are privately-owned or public, owners would benefit from digestion byproducts. This scenario requires high-quality feed stock to be delivered from waste haulers or sorted and collected by the owners of the digester by means of curbside collection or other methods.

This method is a way to pilot co-digestion on a small scale before implementing at a larger scale.

*This scenario was derived from conversations with plant operators (no formal case study).

Scenario 2: Co-digestion occurs at independently-owned AD systems (e.g. at a college institution or community buildings)

Co-digestion would occur at independent AD systems owned by private entities; in this scenario, owners are responsible for the collection and pre-processing. If substantial generators of food waste were to purchase and operate private AD systems, this could potentially divert a considerable amount of food waste currently going to landfills. Financial incentives like tax benefits should be considered to encourage owners to co-digest their food waste and allow competition.

Case Study Example: Michigan State University’s Anaerobic Digestion Program [7]

Michigan State University has anaerobic digesters on campus to not only reduce waste from campus, but to create energy for several campus buildings. This system utilizes approximately 17,000 tons of food per year and generates over 2.8 million kWh of electricity per year. The organics feedstock of the digesters includes FOG, food scraps, and cow manure. The total cost of the project was about $5 million and the university expects a payback period of 5 years.

Scenario 3: Pre-processing at transfer station followed by AD at a WWTP

A public-private partnership between a city’s WWTP and private waste company could facilitate this scenario. For example, the city would take responsibility for energy production while the private waste hauler would be responsible for pre-processing food waste to be sent to the city’s WWTP. This scenario requires a feedstock of organics that is acceptable to use (free of contaminants) at the WWTP, and a WWTP with surplus digester capacity.

In this scenario, either party could be responsible for community education and outreach. An investment into community outreach programs and public-private partnerships may significantly reduce pre-processing cost. Separating community outreach, food waste collection and processing, and energy production may be viable for certain cities with willing partners and funding. Private entities can also assume responsibility to construct, maintain, and operate biogas infrastructure and equipment in return for city grants, leasing, tax breaks, or any financial incentive favorable to both parties. [9]

Case Study Example: Central Marin’s Commercial Food-to-Energy (F2E) Initiative [8]

Central Marin’s Commercial Food-to-Energy Initiative is a public-private partnership between Marin Sanitary Services (MSS) and Central Marin Sanitation Agency (CMSA). MSS, a private company, operates a transfer station and upgraded the facility for food waste preprocessing before sending to CMSA’s regional WWTP. MSS is also responsible for community outreach programs, training, and collection services.

The MSS community outreach program involves training and frequently monitoring kitchen staff at commercial businesses. Tools for successfully reducing contamination at these businesses include labeling and signage, kitchen layout, as well as internal and external collection containers. Additionally, contaminants are continuously removed manually on the tipping floor of transfer stations before dumping on the truck. Then, a conveyor with hoppers, belts, and magnets is used to remove any leftover contaminates, ultimately creating a high-quality feed stock. The material is then taken to CMSA in a slurry form, where it is put into digesters for biogas production. CMSA takes in an average of 15,000 gallons of FOG per day and up to 4.2 tons of food waste per day, up to six days a week. Their WWTP produces an average of 7 MGD of wastewater.

MSS pre-processing equipment costs $530,000, with an annual operating cost of about $130,000, and an annual 5 amortized capital cost of $69,000. CMSA’s facility cost $1.9 million to upgrade for co-digestion, with an annual operating cost of about $103,000, and an annual amortized capital cost of about $250,000.

CMSA’s facility cost $1.9 million to upgrade for co-digestion, with an annual operating cost of about $103,000, and an annual amortized capital cost of about $250,000. Other partnerships to reference: Los Angeles Sanitation District works with Waste Management for co-digestion. Waste Management manages the collection and pre-processing to create a food waste slurry to be sent to Joint Water Pollution Control Plant in Carson, CA, which on average, treats 280 MGD of wastewater.

Scenario 4: Co-digestion at a local transfer station

Pre-processing and co-digestion would both occur at a local transfer station, saving time and money on transferring processed food waste to another location for co-digestion. Organic waste would be pre-processed, and then directed to digesters close by for co-digestion. Different types of digestion can occur at different transfer stations around the city. Transfer stations can be owned by the city or privately depending on incentives set by the city. This scenario can be an opportunity to provide renewable natural gas fuel for a waste company’s truck fleets.

Case Study Example: Clean World and Sacramento County [10]

In a public-private partnership between Sacramento County, Clean World Partners, and Atlas Disposal, these agencies collectively convert food waste into renewable natural gas for trucks at the County’s South Area Transfer Station. The County’s organic waste recycling center processes 100 tons of food waste per day. Clean World Partners provided the anaerobic digesters and Atlas Disposal Industries collects the food waste.. Clean World Partners received a $6 million grant from the California Energy Commission that allowed them to process 100 tons of food waste per day compared to their original 25 tons per day. Also, the facility generates $1.1 million for tax revenues for the city, county, and state. [11]

Final Recommendations

1) Consider All Factors

Cities looking to use co-digestion technology in local wastewater treatment plants should consider a number of factors, such as:

- Operational and maintenance cost, and associated factors

- Financial factors

- Community impact

- Capacity/infrastructure factors

2) Be Open to Partnership Ideas

Cities should look for transfer stations for food processing, government cooperation, funding, private partnerships, and incentives to encourage involvement and partnerships. Consider the possible effects federal regulations and permits may have on operations. Additionally, incentives or programs can be put into place to encourage food waste diversion from landfills.

3) Develop Programs

Cities should develop community outreach programs to obtain sorted food waste with less contamination, and look to programs of other cities for program models. Consider pilot or lab program development before full-scale operations.CLICK HERE TO DOWNLOAD REPORT

[0]Benefit-Cost Analysis of Potential Food Waste Diversion Legislation. Industrial Economics, Incorporated, 2017, pp. 1–26, Benefit-Cost Analysis of Potential Food Waste Diversion Legislation.

[1]Food Waste to Energy: How Six Water Resource Recovery Facilities Are Boosting Biogas Production and the Bottom Line . United States Environmental Protection Agency, 2014, pp. 1–31, Food Waste to Energy: How Six Water Resource Recovery Facilities Are Boosting Biogas Production and the Bottom Line .https://www.epa.gov/sites/production/files/2016-07/documents/food_waste_to_energy_-_final.pdf

[2] Raibley, T., Ramirez, A. and Ursillo, P. (2017). Anaerobic Digestion Feasibility Study. King County, Washington. Available at: https://kingcounty.gov/~/media/depts/dnrp/solid-waste/about/planning/documents/anaerobic-digestion-feasibility-study.ashx?la=en [Accessed 20 Aug. 2018].

[3]Rosengren. “Waste Management Taps Anaergia for Organics Pre-Processing and AD in Latest RecycLA Investment.” Waste Dive, 12 Dec. 2017, www.wastedive.com/news/waste-management-taps-anaergia-for-organics-pre-processing-and-ad-in-latest/512716/.

[4]“Industry News: Turning Industrial Waste into Energy Opportunities.” NEWEA – New England Water Environment Association, 10 July 2015, www.newea.org/2015/07/13/industry-news-turning-industrial-waste-into-energy-opportunities/

[5]Dirkes, Karl. The New SEPARATE Waste System Quality Products from Waste through Efficient Waste Separation – Challenges and Potential. SEPARATE Waste Systems, 2015

[6] Williams, Todd, and Tim Shea. Anaerobic Digestion and Co-Digestion Optimization. CH2MHILL, 2013, Anaerobic Digestion and Co-Digestion Optimization, www.ohiowea.org/docs/Williams_Todd.pdf.

[7]“17,000 TPA Anaerobic Digestion Biogas Plant at Michigan State University.” « Recycling « Waste Management World, 22 Oct. 2015, waste-management-world.com/a/17-000-tpa-anaerobic-digestion-biogas-plant-at-michigan-state-university.

[8] “Anaerobic Digester.” Generating Power – Infrastructure Planning and Facilities, ipf.msu.edu/green/practices/anaerobic-digester.html. Central Marin Commercial Food-to-Energy (F2E) Program. (2015). [ebook] United States Environmental Protection Agency. Available at: https://www.epa.gov/sites/production/files/2015-09/documents/dow_0.pdf [Accessed 20 Aug. 2018].

[9]“Codigestion At Water Resource Recovery Facilities.” BioCycle, 3 May 2018, www.biocycle.net/2018/03/12/codigestion-water-resource-recovery-facilities/.

[10] California Energy Commission. “CALIFORNIA CLEAN ENERGY TOUR CLEANWORLD SACRAMENTO BIODIGESTER.” California Energy Commission, http://www.energy.ca.gov/tour/cleanworld/ [11]“Anaerobic Digest.” BioCycle, 23 Apr. 2014, www.biocycle.net/2012/07/17/anaerobic-digest-17/.