CHLOE NEY MAY 31, 2019

Launching the Biogas Generation & Food Recovery Initiative in 2018, Global Green sought to help communities address area-specific barriers to clean energy. Continuing this initiative through 2019, Global Green is offering a partnership opportunity to communities interested in addressing these barriers in order to develop scenarios for expanding local food waste-to-biogas generation.

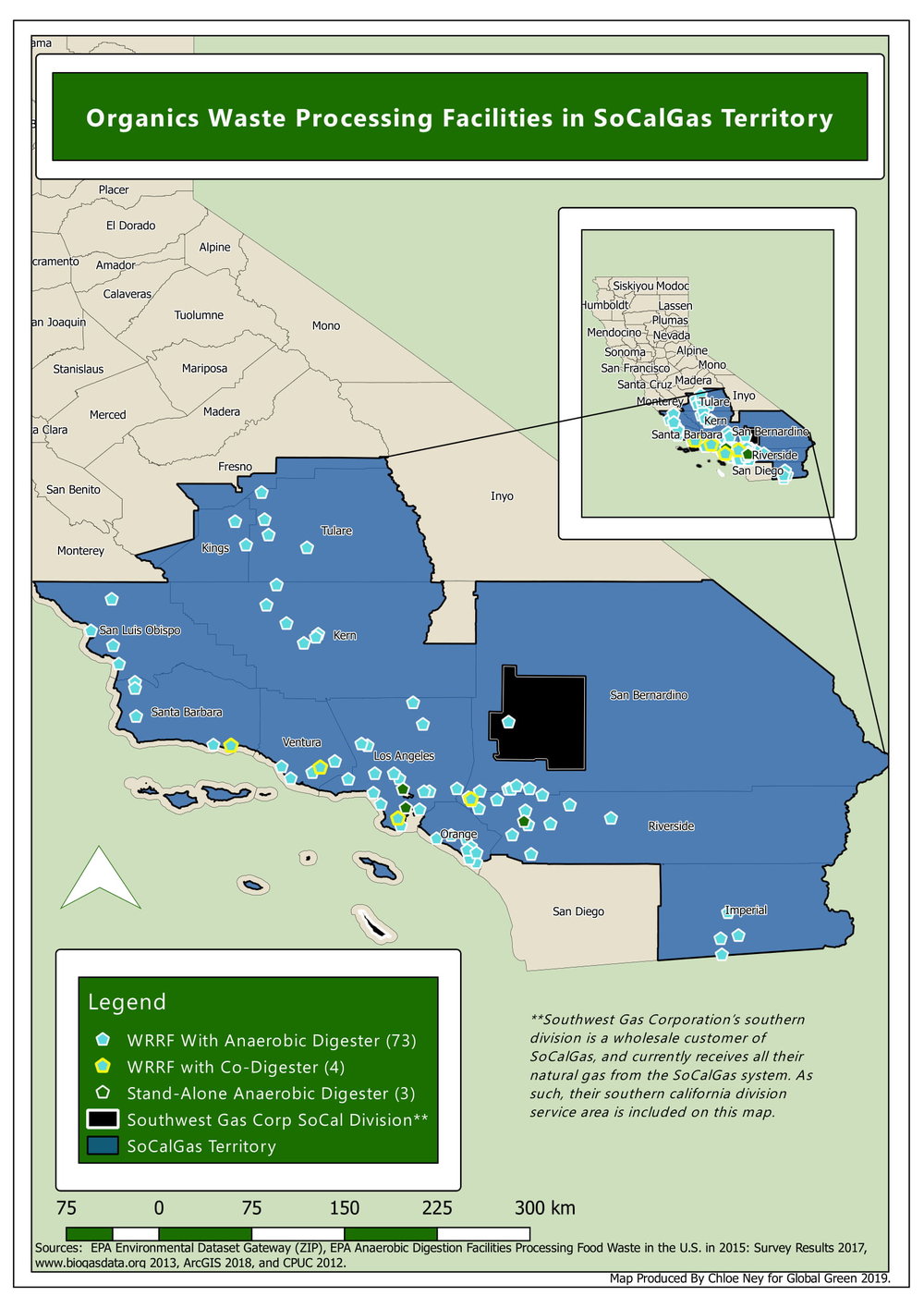

The first step of this process involves working with partner cities to identify existing infrastructure and assess their baseline food waste processing capacity. Locating existing infrastructure presents an opportunity for cities to expand on their existing infrastructure with the addition of technologies to avoid the potential costs of building new facilities altogether. Locating these facilities also provides Global Green with location-based data that can be used to create a comprehensive map identifying these facilities.

Using Quantum Geographic Information System (QGIS), a free and open source Geographic Information System (GIS) platform, every facility address that could be found was geocoded to create unique location points to ultimately create a map that identifies existing facilities.

In preparation, Global Green has searched within SoCalGas territory to locate processing facilities with on-site anaerobic digesters. These types of facilities convert organic matter (i.e. food waste), in the absence of oxygen, into methane-rich biogas, which can be used for heating, vehicle fuel, or for generating electricity.

In the State of California, anaerobic digestion is facilitated in three main facility types which convert food waste to biogas:

1) Stand-Alone Digesters

Stand-alone digesters are typically built to process only food waste, and can be further divided into two sub-categories: multi-source food waste digesters with the capacity to accept and process feedstock from multiple sources, and industry-specific digesters that are typically designed adjacent to a food- or beverage-processing plant in order to process waste from that specific plant.

2) Water Resource Recovery Facilities (WRRFs) with Digestion Technologies

WRRFs in the U.S. have anaerobic digestion technologies designed to manage wastewater solids, but about 20% of existing facilities also have the capacity to co-digest food waste from off-site sources (EPA 2018).

3) On-Farm Digesters

On-farm digesters are typically designed for manure management but also co-digest food waste. To note, on-farm digesters are not identified in the map below, because there aren’t any existing facilities located within SoCalGas service area.

The map generated below displays anaerobic digestion facilities located in SoCalGas’s service area, including those within the South West Gas Corp territory serviced by SoCalGas. Distinguishing between the three types of digesters described above, the map also identifies WRRF’s with anaerobic digesters that are not co-digesters. While these WRRF’s do not accept food waste (they only have the capacity to process and treat wastewater), these facilities present an opportunity for cities to expand on their existing infrastructure with the addition of technologies that facilitate co-digestion, avoiding the potential costs of building new facilities altogether.

Co-digestion is “a process whereby energy-rich organic waste materials (e.g. Fats, Oils, and Grease (FOG) and/or food scraps) are added to dairy or wastewater [anaerobic] digesters with excess capacity. In addition to diverting food waste and FOG from landfills and the public sewer lines, these high-energy materials have at least three times the methane production potential (e.g. biogas) of biosolids and manure” (EPA 2016). Introducing co-digestion to WRRFs often presents an opportunity to power these facilities with any excess biogas produced on-site, thereby creating added economic and environmental benefits that can help offset costs.

The geospatial analyses conducted in generating the map below show that, within the SoCalGas service area, there are:

- 73 WRRF’s with anaerobic digesters

- 4 WRRF’s with co-digestion facilities (Hill Canyon Wastewater Treatment Plant, Inland Empire Utilities Agency – Environ/The Regional Water Recycling Plant No. 5 Solids Handling Facility, El Estero Wastewater Treatment Facility and Los Angeles Sanitation Districts Ad Pilot/Joint Water Pollution Control Plant)

- 3 stand-alone anaerobic digesters (Kroger/Ralphs – Compton Distribution Center, Costa Mesa Sanitary District Ad, and Anheuser-Busch Brewery)

- No on-farm digesters